Tank and Line Testing

Underground storage tank testing to the finest tolerances available. Get rapid and absolute results determined by scientific methods.

Buried fuel tanks and the lines they use to feed fuel to your forecourt, are a high risk to the environment if not monitored and maintained correctly. Leaks in these fuel tanks both inward and outgoing, represent a double risk to your business. Ingress of water and egress of fuel each result in expensive consequences for your site.

Invest in The Best

Using the Leighton O'Brien precision testing equipment and methods, Petromonitor is able to deliver the fastest and most accurate tank and line leak test in the world. No leak type exists that escapes the science of the mass-based process in use by our highly trained teams.

Our line leak test can expose a leak as slow as 0.09 litres per hour. Lines, unions, fittings and joints represent 70% of most leaks at a typical fuel site.

Test once - Report Rapidly

Digital Results Based Reporting

Ensure Operational Stability of Your Sites

Change The Way your reduce your network RISK

Most serious maintenance issues arising on fuel sites are found to be due to issues related to the original installation. Removing this risk from your network has obvious benefits to future performance and compliance.

Certified Testing Methods

Minute Tolerance Measurement to 0.09 Litre/hr

Independent Testing

Instant Results - Fast testing

Precision, Patented Technologies

Our methods and processes are uniquely precise and accurate to minute tolerances.

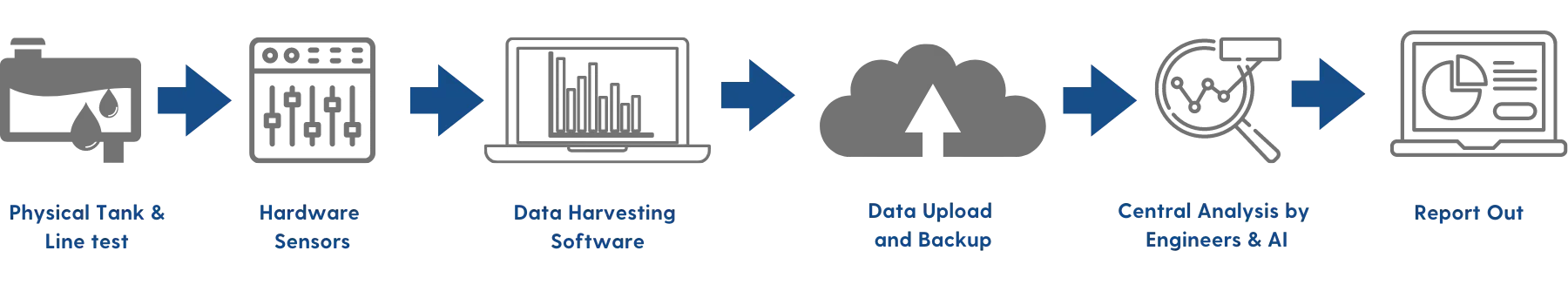

How it works

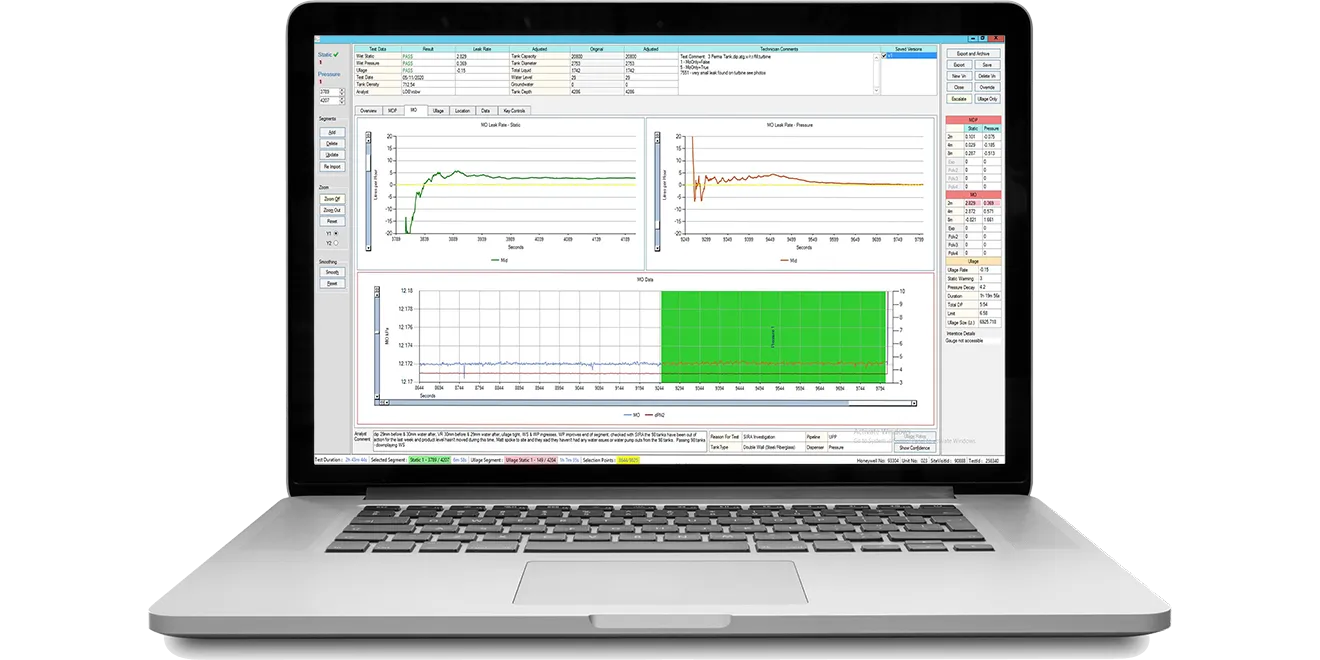

Not all tank tests are equal. Most testing companies use technology which is reliant on subjective assessments by human beings. As a result these testing methods are not accurate and false results are frequent.

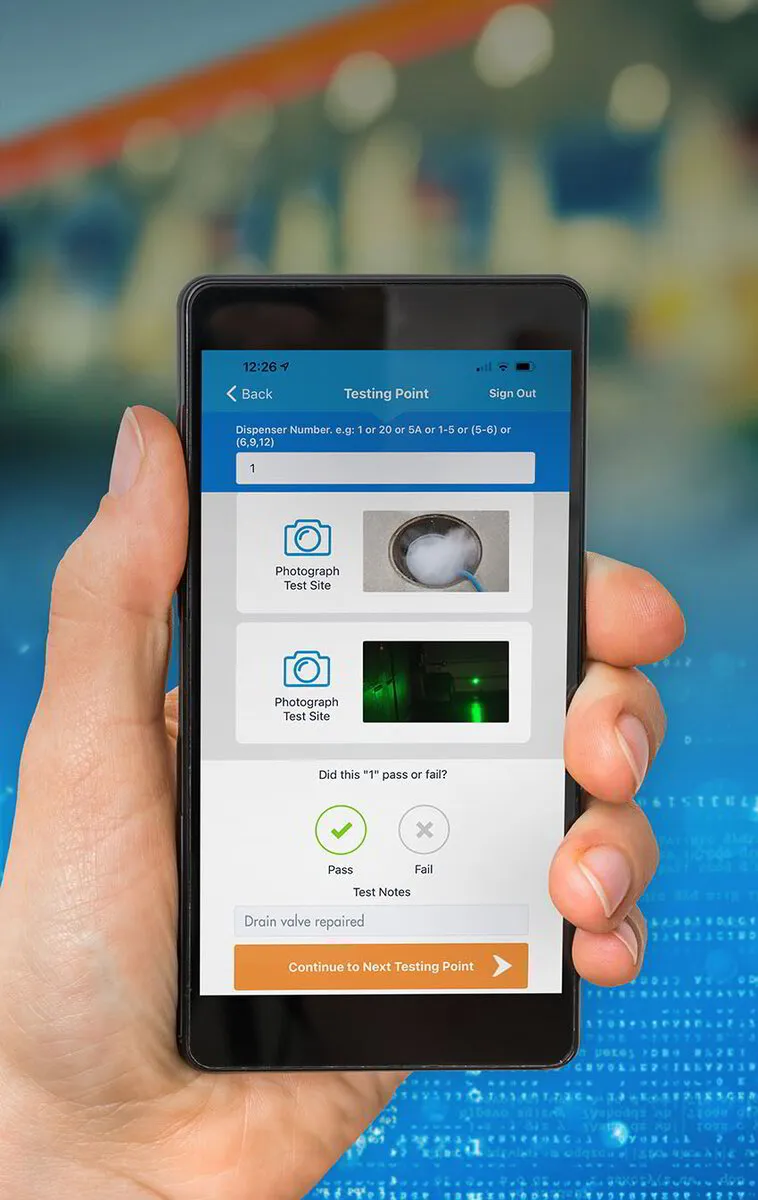

With Petromonitor and the Leighton O'Brien technology, we use digitally verified parameters to give exhaustive and absolute measurements to within minute tolerances. This ensures uniformity and confidence that each test adheres to local environmental compliance regulation, time after time.

This stringent quality control of testing also means that testing needs to be done less frequently and that your assets are in good condition.

- US EPA certified as the most accurate underground tank test globally

- Certified test time is 67 minutes

- Uses multiple differential pressure sensors for automated mass readings

- Tests tank and line at the same time

- Tests the interstice as part of the tank test

- Can test all tank types at any fill level with any product

- Instant feedback to technicians, inc. live leak rate

- All readings are digitally stored and centrally analysed by qualified engineers

- Fastest and most accurate US EPA certified test – 3 minutes of data required for an empty line, 17 minutes for a wet line test

- Volumetric test that can perform both pressure and vacuum testing

- All line conditions can be tested including dry, wet and partially wet lines

- Certified for all pipe manufacturers including steel, plastic, single and double walled

- Readings are digitally recorded, stored centrally and analysis completed by engineers

Watch a demo of our tank and line testing process

Fast, accurate leak detection. When it comes to tank and line testing, you need the best technology available, meeting the highest environmental standards. Trusted and respected, our range of leak detection technologies are certified to the US EPA’s rigorous certification protocols.